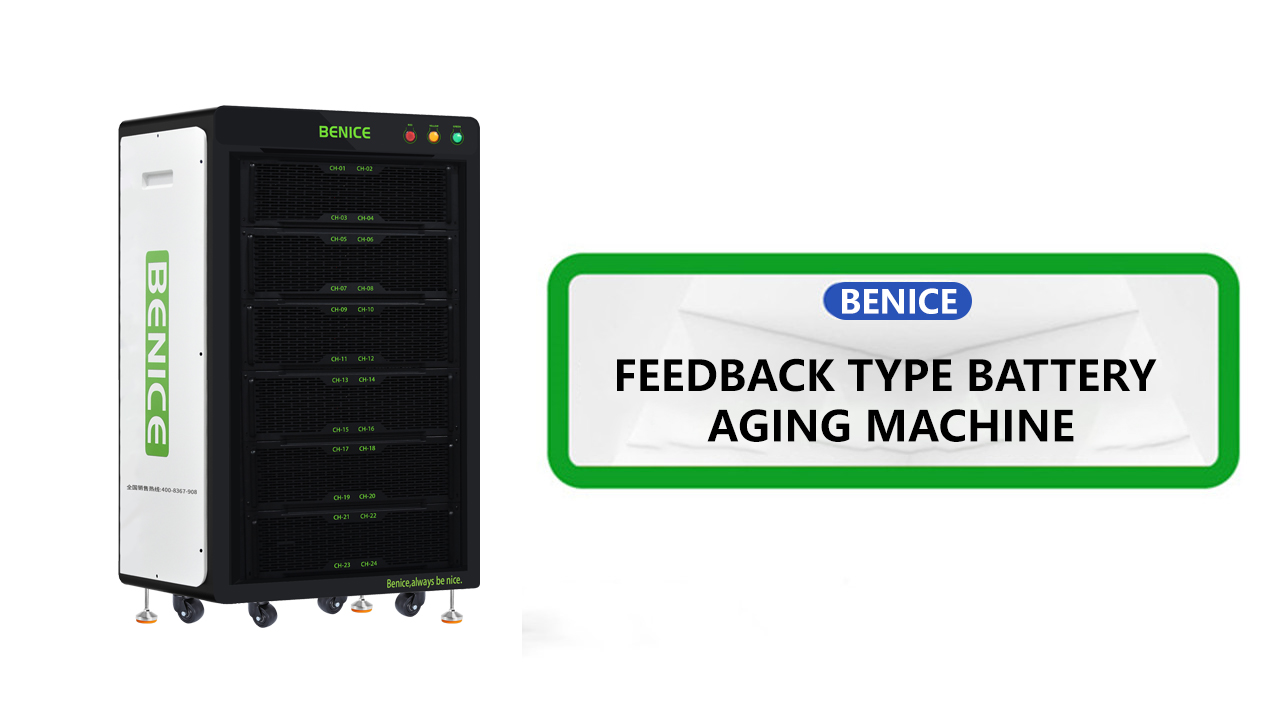

Feedback type battery aging machine

Product Features

● The energy flows in two directions, and the discharge energy is fed back to the power grid efficiency ≥ 93% (DC bus efficiency).

● DCAC module adopts space vector modulation technology, digital control and reliable grid connected inverter.

● DCDC module adopts advanced PID control technology and multiple software or hardware protection mechanism to ensure the stability of equipment operation

● Fast conversion of output current and no overshoot of current can avoid the impact of equipment on batterypack,Support the same port and different port battery aging test.

● Charge or discharge status LED indication, charge or discharge curve analysis diagram, support code scanning function.

● The middle computer and the lower computer both use 32-bit ARM chip can bus communication, the data transmission speed is fast and the performance is stable.

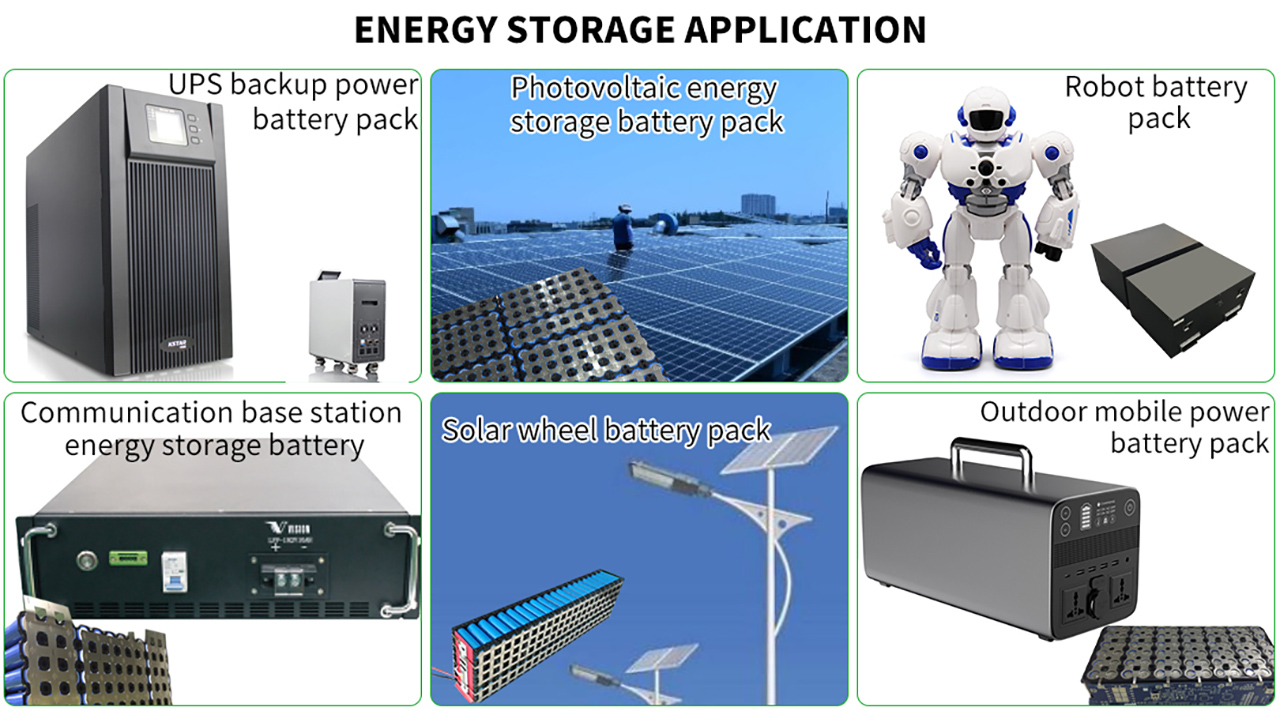

Application Areas

In fact, the principle is almost the same. One reason is to completely wet the electrolyte. On the other hand, some active components in the positive active material are deactivated by some reactions, making the overall performance of the battery more stable. Many companies want to do this process and accelerate through high temperature aging method, but high temperature aging requires attention to control time and temperature.

Because high temperature aging will produce more active material deterioration than normal temperature aging, if it is well controlled, the active components will react completely, the battery characteristics will be stable, the control adverse reactions will be excessive, the electrical properties will decrease, the capacity will decrease, the IR will increase, and even the possibility of liquid leakage very high.

After-sale service

What is the function of aging cabinet?

In the past, aging generally referred to battery placement after the first charge after assembly and injection were completed. It can be aged at normal or high temperature. Its role is to stabilize the properties and composition of the SEI film formed after the first charge. The aging process has electrochemical kinetic changes, which is of great help to the stability of the SEI and can promote the stability of the electrochemical system.

With the rapid development of the battery industry, the definition of battery aging has also quietly changed. Due to the high requirements for batteries, in theory, the four steps of battery cell forming, capacity tester, testing, and aging require battery aging, and battery aging cabinets are also required in the PACK assembly line.

Therefore, the battery aging cabinet mentioned now is not a specific device, but a system, which runs through the process of forming, dispensing, testing, and aging detection in battery production, which are different but related to each other. Secondly, the different battery manufacturing processes and battery materials of different battery factories make the functional requirements of battery aging cabinets different. Therefore, the current battery aging cabinet needs to be tailored.

In actual use, considering the inconsistency between production capacity and market demand, some battery factories have adjusted the aging steps in order to increase production capacity on the premise of ensuring quality. The parameters that need to be adjusted for each production line mainly include temperature, space, time and sequence, which are designed according to the battery characteristics. The tray, logistics line and size of the battery cabinet are also customized according to the size of the battery.